Trenchless Technology Magazine highlights why the leading CIPP-Installer has outfitted its fleet and offices with ITpipes Mobile and Web

For more than 50 years, Insituform has been rehabilitating pipelines all over the world using its flagship cured-in-place pipe (CIPP) lining. As the inventors of CIPP, the company takes great pride in delivering a top-notch product and client experience. A finished project means the client not only gets a pipe with restored structural integrity and reduced infiltration but also vital asset management data via videos and reports.

When Insituform’s existing CCTV inspection software was no longer planning to meet industry needs, the company began the search for a new software partner. Anyone who has implemented a new software system knows that implementations are akin to the adage of “ripping off a band-aid;” it will be painful but it’s best to get it over with. The company wanted a software that was future-ready and would evolve as they explored new technologies and methods.

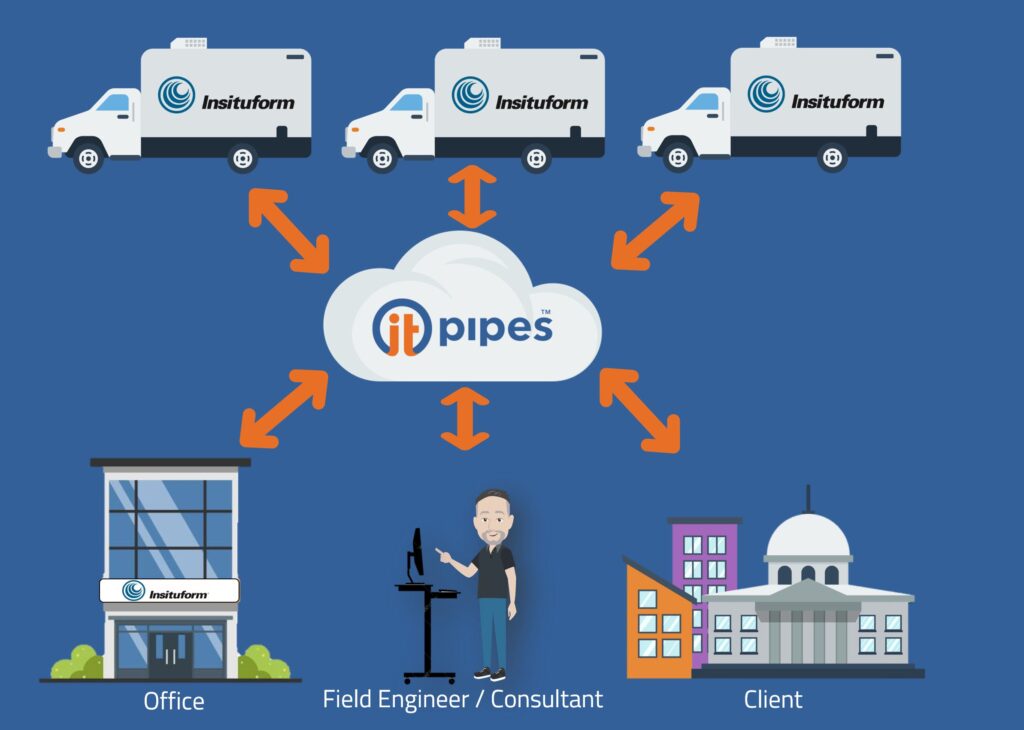

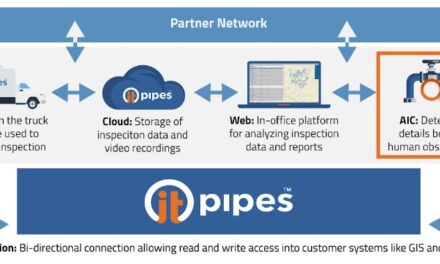

After much research, Insituform selected ITpipes as their partner. ITpipes not only solved their initial challenge of having a software partner that would be NASSCO PACP V7 certified, but also offered a host of solutions to increase efficiency. Insituform’s workflow was started underground. However, with a little effort, it would eventually end up in the cloud.

“We realized the benefits of digitizing these processes and felt confident that our business and our customers would quickly recognize the value”

Tim Bremmer, Vice President of Applications

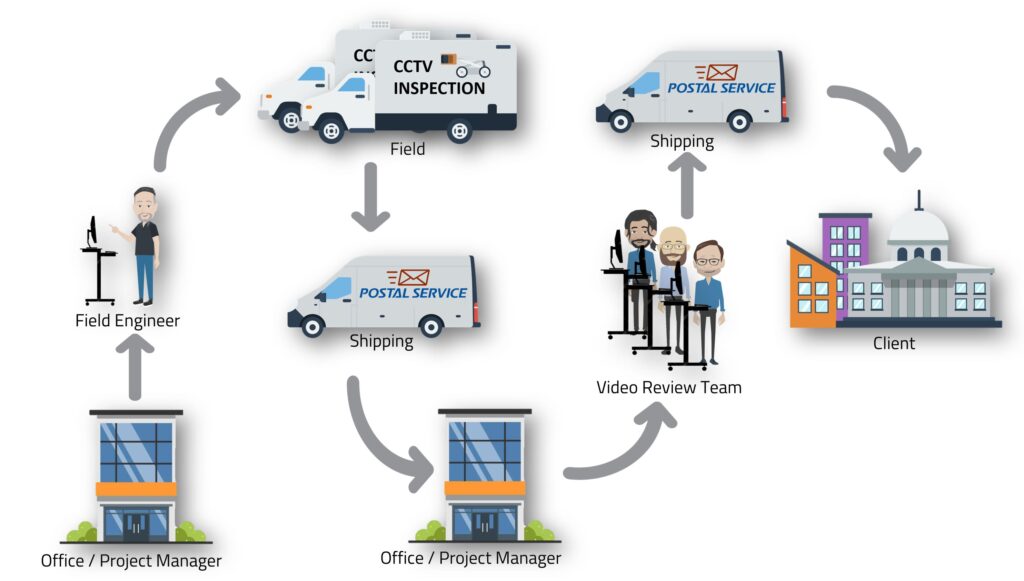

Tim Bremer, Vice President of Applications, said, “We realized the benefits of digitizing these processes and felt confident that our business and our customers would quickly recognize the value. First, Video Data Integrity – A goal of zero lost videos, which could lead to crew re-work. Second, Installation/Mobilization Costs – we wanted the ability to QC work before a crew relocates to another job site. Third, Efficiency – reduced data entry for crews and eliminating shipping costs for hard/thumb drives.”

“We had multiple people in the CCTV department, and the work never stopped,” said Billy Loche, Video Department Manager, Insituform. “Since every truck was siloed, all the inspections and videos came in via hard drive, typically at the end of the projects. This created ebbs and flows in workloads for staff and Insituform wanted to manage the workflow more smoothly.”

To learn more about how Insituform evolved to the cloud and left behind a workflow where data was siloed, relied on physical hard drives, was often bottlenecked, check out the full Trenchless Technology Article here.

Interested in other Trenchless Technology articles featuring ITpipes Clients?

Interested in seeing how ITpipes can help streamline your company’s workflow?